The following is a collection of frequently asked questions:

When testing shrapnel, please pay attention to some matters as follows: 1. When installing shrapnel to place the working slot, make sure that the working slot where the shrapnel is placed is on a flat plane. 2. During shrapnel installation, try not to press the shrapnel with your fingers. If the shrapnel has been pressed with fingers, try not to use it on the product. 3. Shrapnel installation of the work slot needs to leave extra space, to avoid shrapnel pressure deformation caused by shrapnel outward extension, if the margin is not enough to cause shrapnel pressure deformation and affect the normal service life of the shrapnel. 4. The use of shrapnel do not always press the shrapnel, to avoid causing malfunction or damage, the key frequency should not be too fast, generally in the 3 ~ 5s once not less than this number. 5. Shrapnel can not be soaked in water for a long time, in the water for a long time the surface will line into a layer of oxide film, affecting the conductive. 6. Shrapnel life test, it is recommended that the use of ball-type silicone head, to avoid the test process under pressure leading to shrapnel damage. 7. Shrapnel pressure test, need to be measured according to product specifications, testing pressure to pre-release the stress of the shrapnel, the first pre-press 10 times before the pressure test. The pressure test head has specified requirements, product specifications have test requirements. 8. When using shrapnel, try to use the same batch of shrapnel and avoid mixing different batches of shrapnel. Translated with DeepL.com (free version)

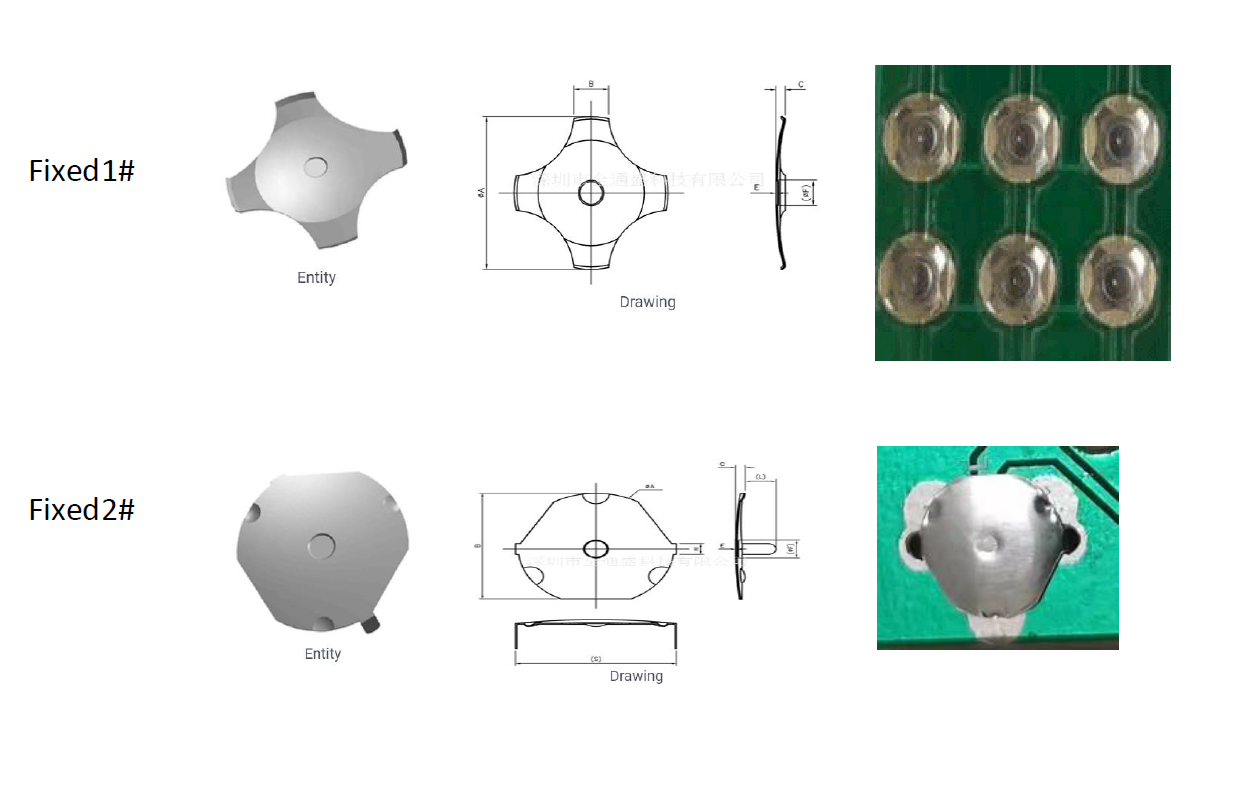

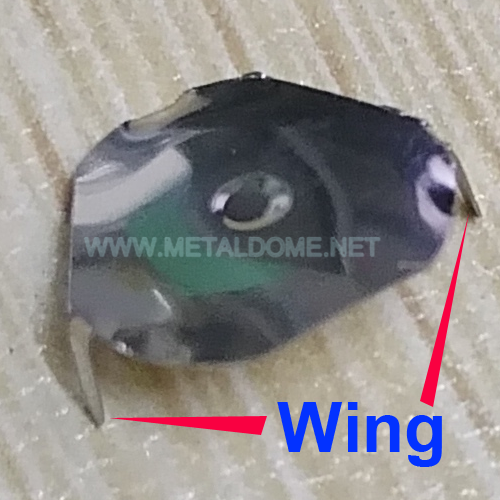

There are two common fixed method for metal dome. 1. Adhesive tape.(Please review Fixed1# of the below screen ) 2. Some particular dome series with insertion wing for securing on to PCB. (Please review Fixed2# of the below screen )

According to the different use of the situation, simulation test pressure. Because of different use of the crowd, the strength of the press has some differences. The size of the shrapnel also matters. Usually, the finger presses the button with a force of

Different batches, because the material batches, equipment and process may not be completely the same, the same product should not be mixed with different batches of a single use.

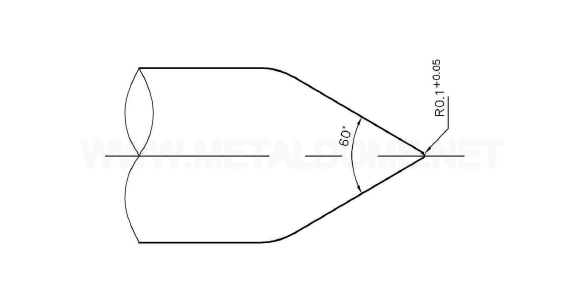

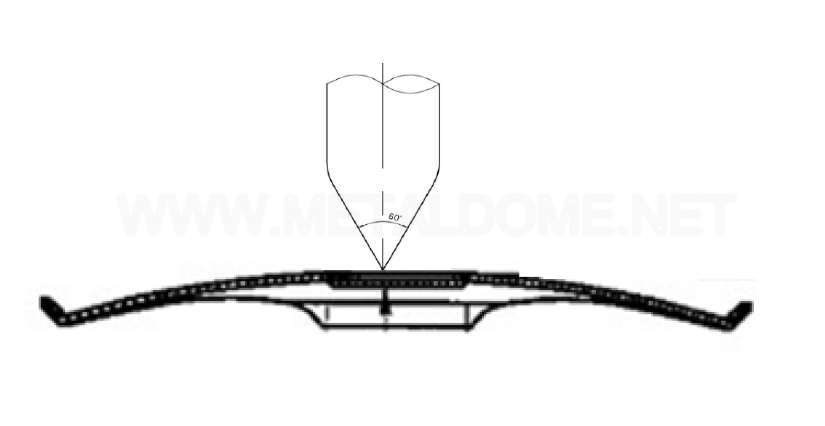

Unless otherwise specified, force test probe should be hard, non-elastic pointed head ( Please review the screen of the pointed head).

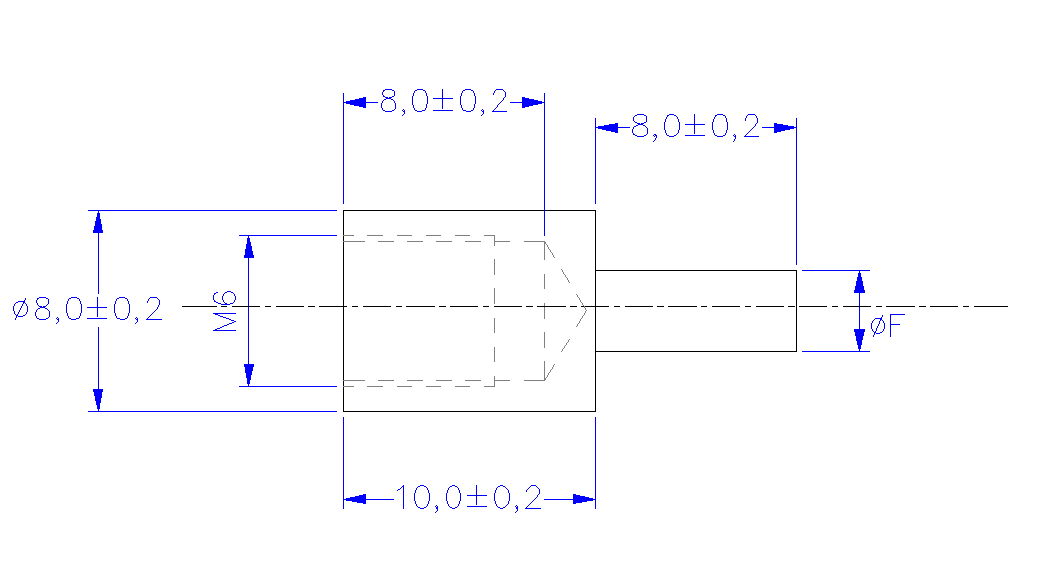

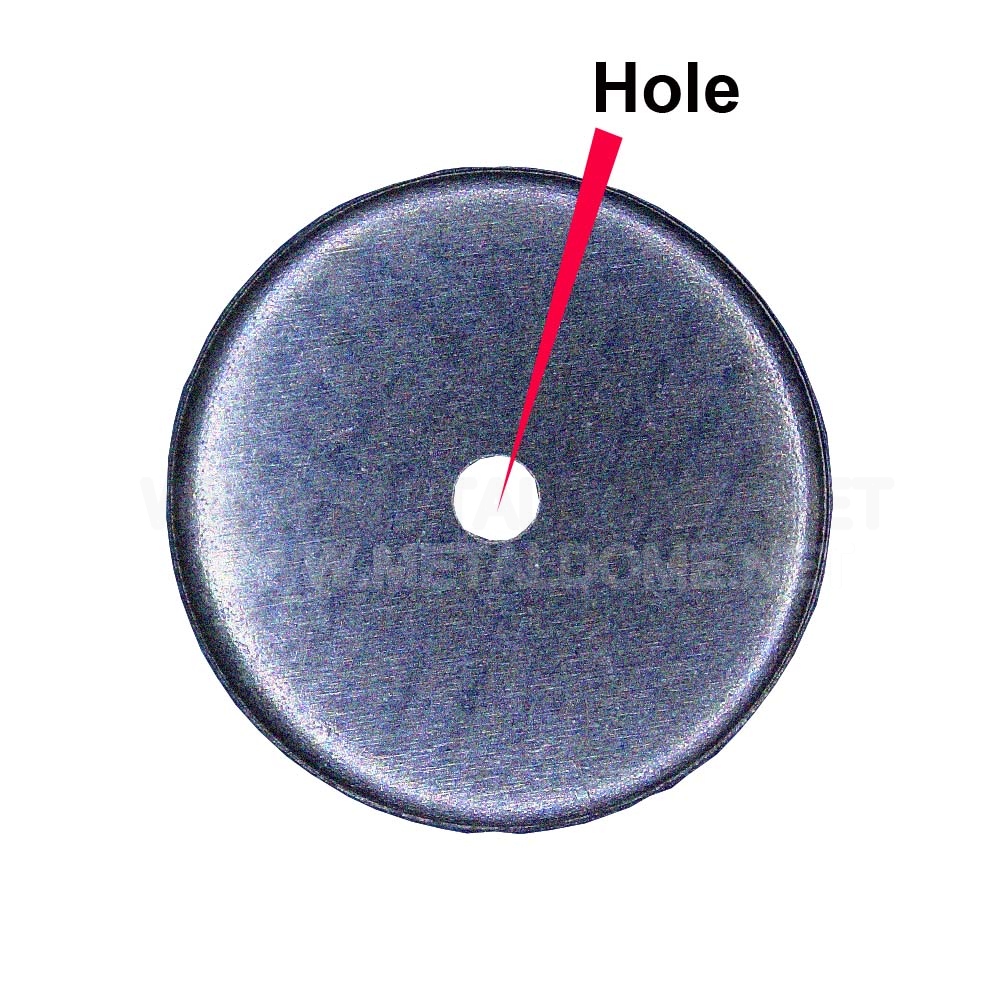

Due to the customer's special shrapnel requirements or center hole shrapnel requires the use of flat test head for load (pressure) test, load (pressure) test head F diameter 2.0mm, 3.2mm, 4.2mm, 5.0mm, etc., flat load (pressure) test head as shown in the figure below.

Standard size shrapnel usually uses a pointed tip (0.3-1.0mm) unless special shrapnel requires a test head such as a 2.0mm flat test head.

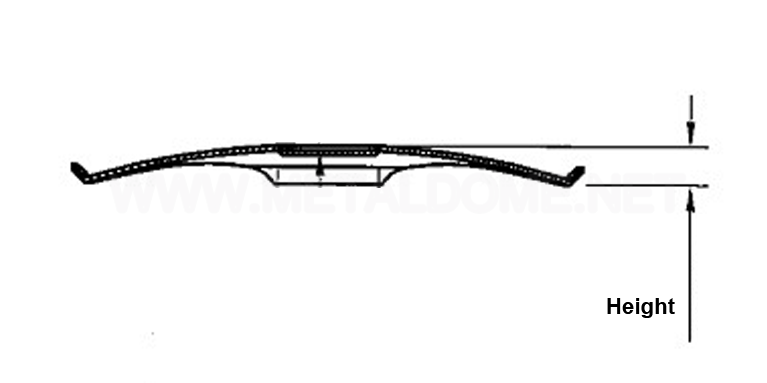

Dome height without any force exerted. Please review the height of the metal dome is below screen.

When testing the pressure of the shrapnel, you need to measure it according to the requirements of the product specifications. When testing the pressure, release the stress of the shrapnel in advance and press the press 10 times before testing the pressur

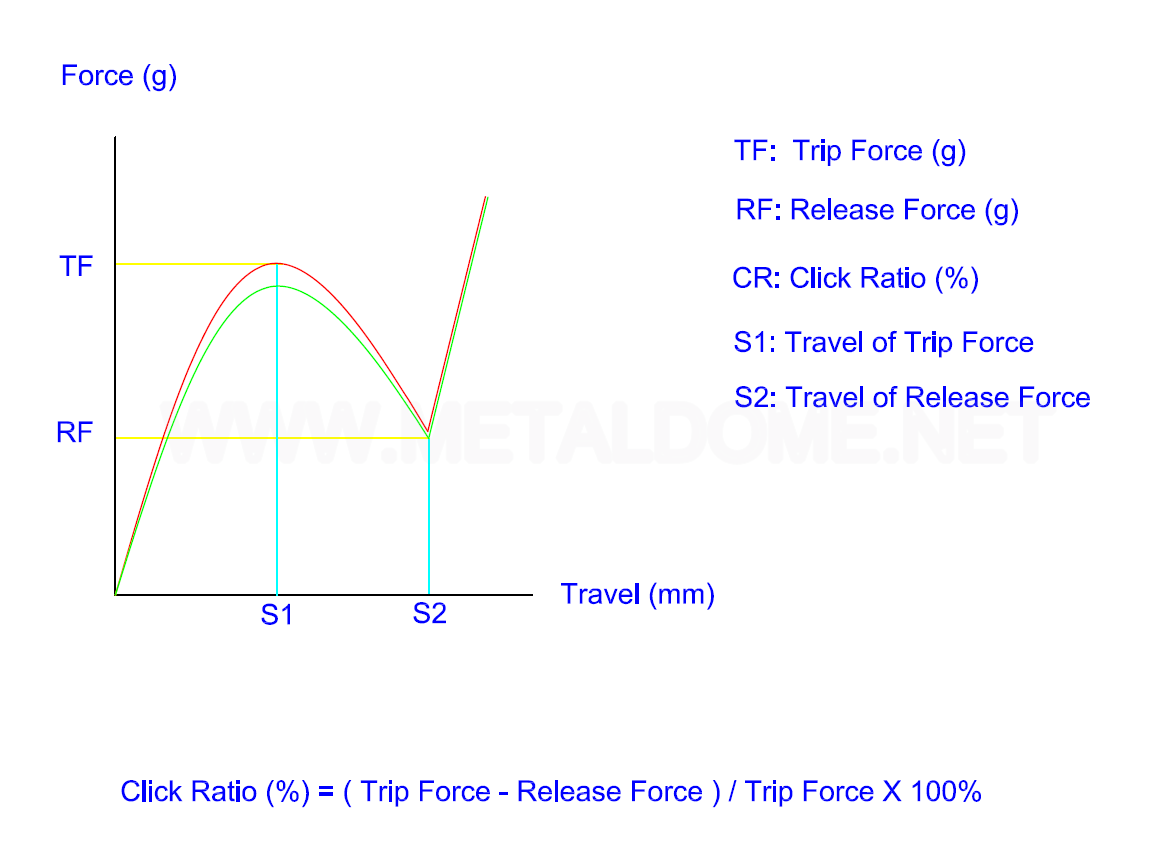

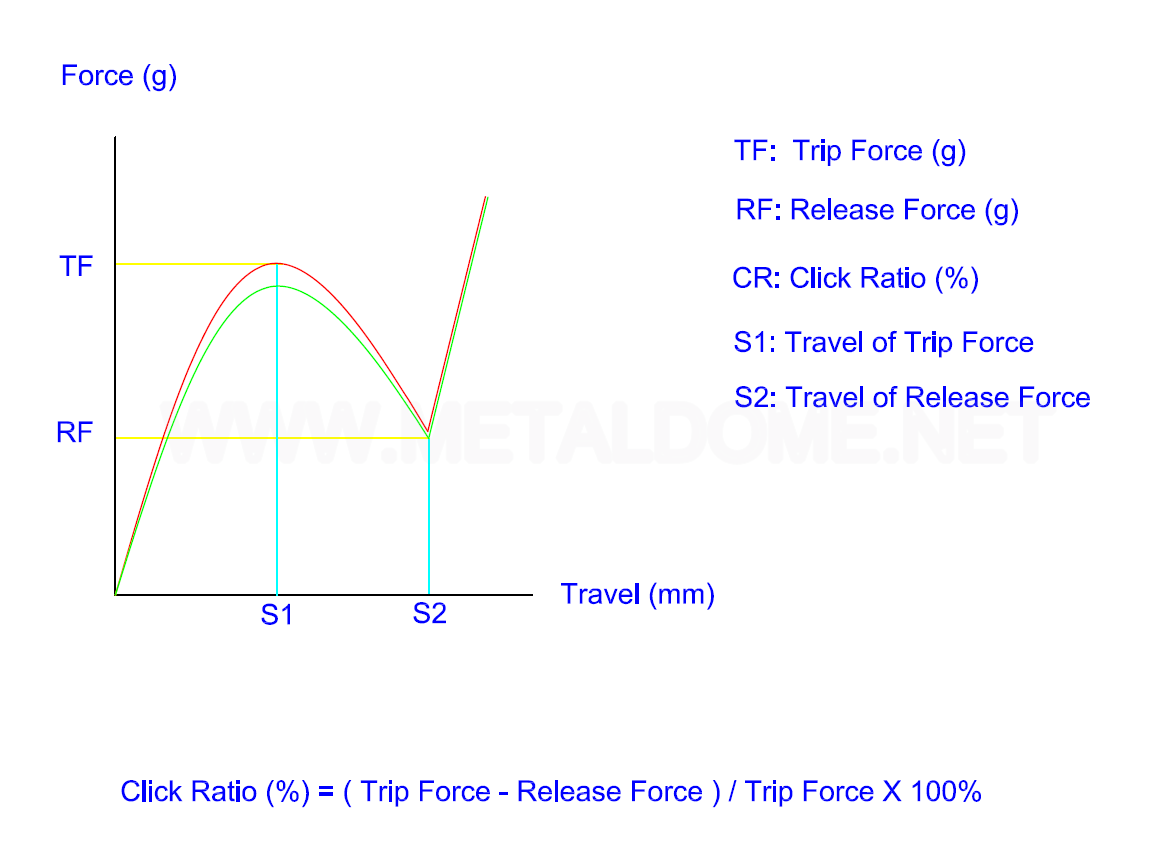

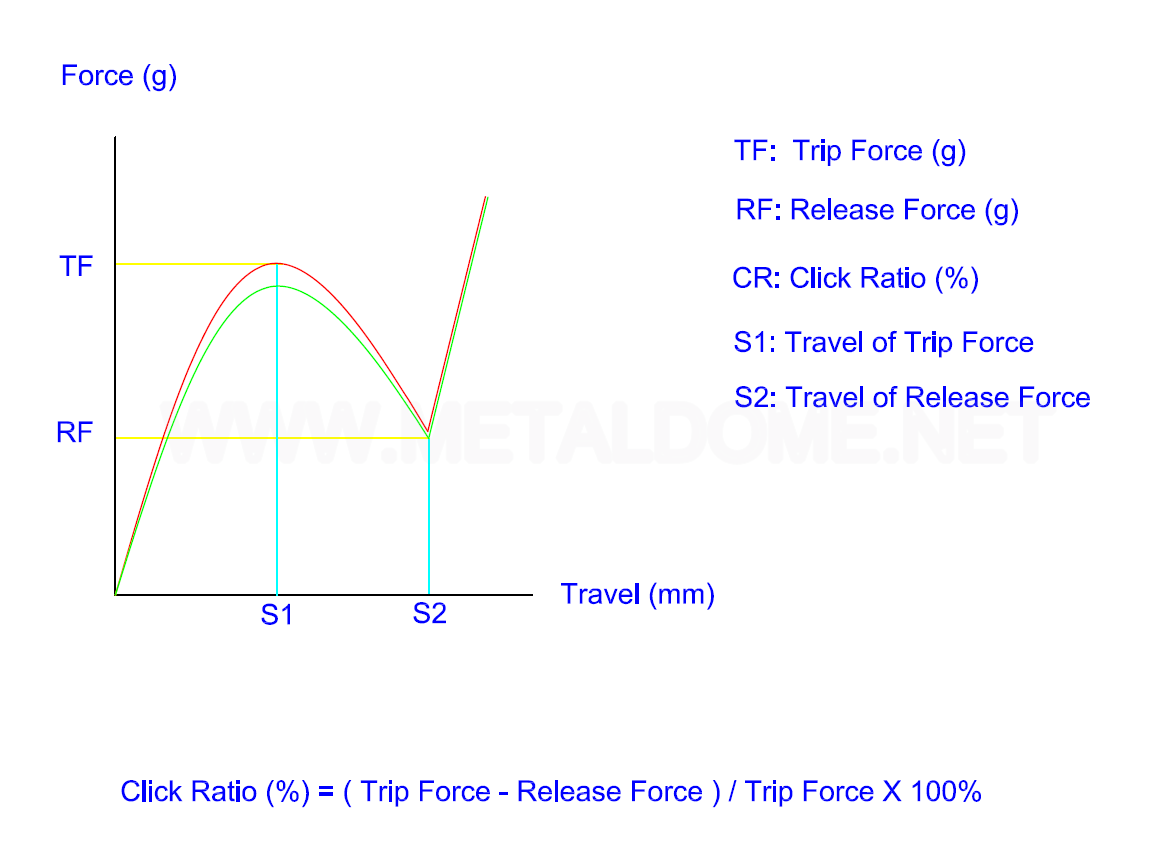

The minimun force required to actuate the metal dome. Whenever the pressing force is greater than this value, metal dome start to snap downward.

The minimum force required to maintain the metal dome at the stage of contact. Whenever the pressing force is lower than this value, metal dome start to spring back to original shape.

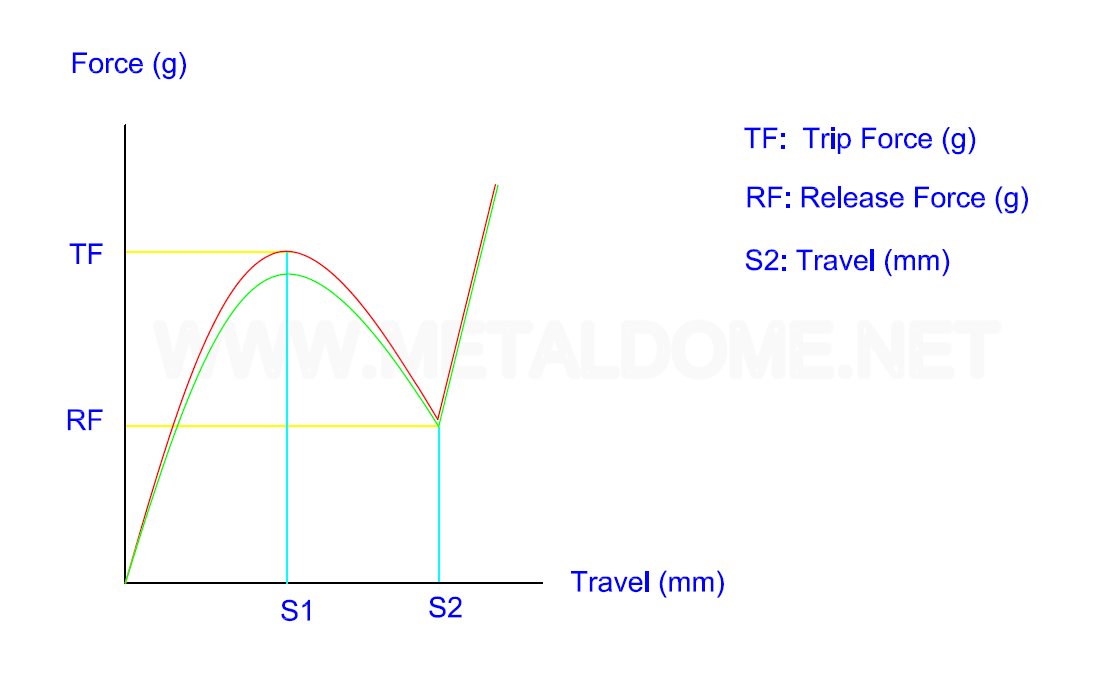

Moving distance of contact point when metal dome actuated. Pleas review S2 (Travel) of the below screen.

Click Ratio (%) = (Trip Force - Release Force) / Trip Force X 100% is an measurable index to reflect contact "feeling". Please review 'click ratio' of the below screen.

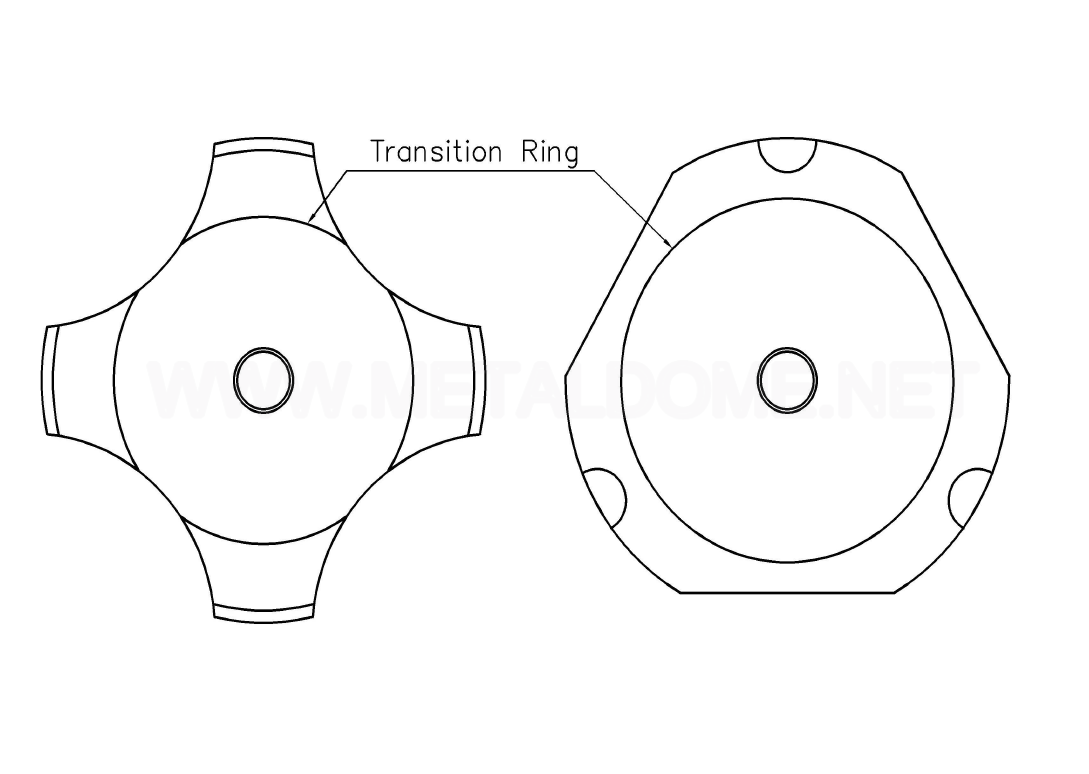

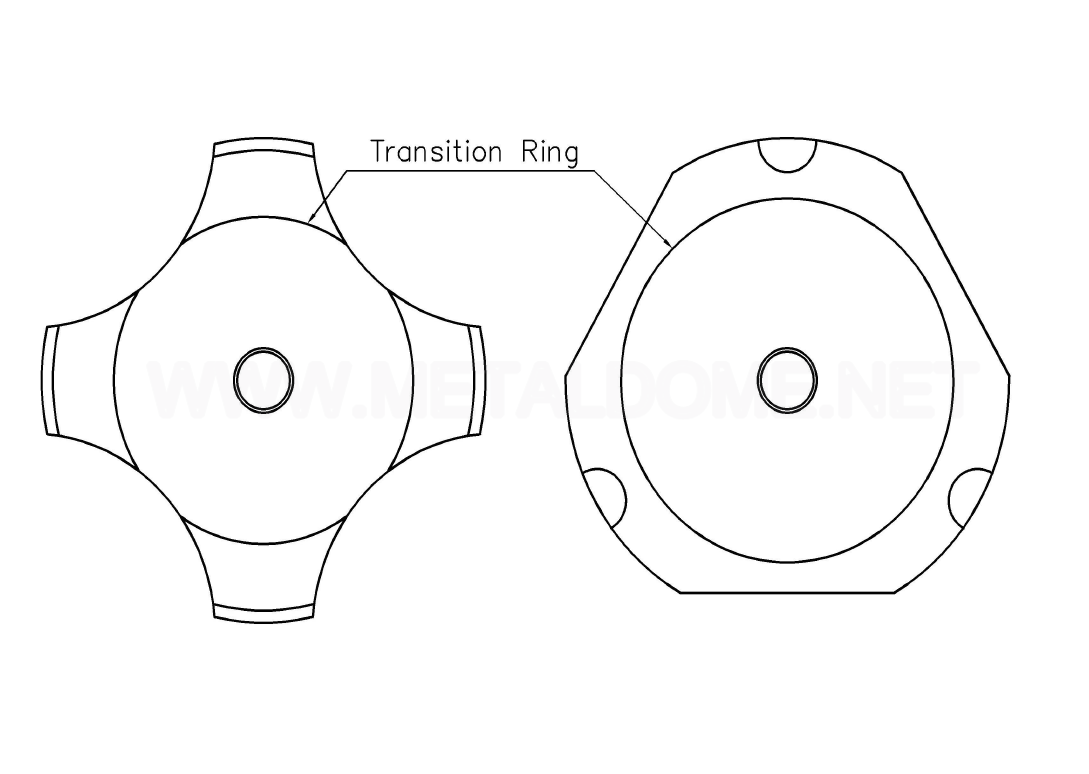

A visible ring on dome surface. This is the portion that dome body transite to the dome leg, it functions as a hinge point to force the metal dome to snap back to its original shape after being pressed.

The function of transition ring just like a hinge, it forces the metal dome to snap back to its original shape after being pressed. Therefore, any damage on the transition ring may cause the metal dome collage.

For some model, there is a concaved feature located at the dome center called as "dimple". The dimple has two function: 1. used as an ID mark. 2. increated the contact area.

Some shrapnel is mainly used on the panel with a backlight, the shrapnel hole can show the key through the light on the panel.

The function of the side wing is to fix the shrapnel on the PCB board for easy assembly. The triangular shrapnel with side fins is shown in the figure below.

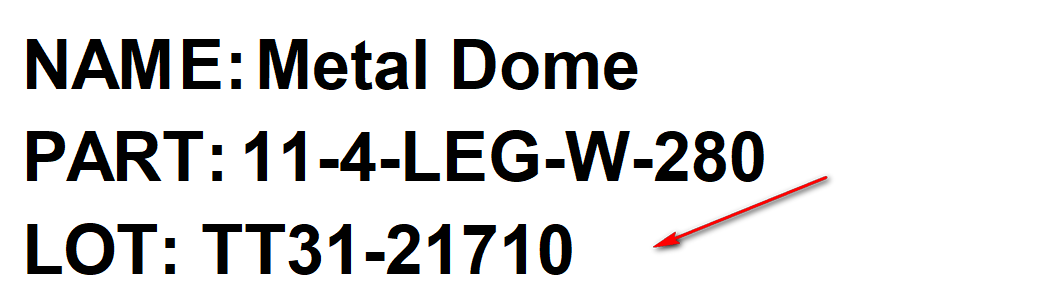

The Lot no. created with the purpose to distinguish the metal domes manufacture under different conditions, such as different press, different tool, or re-setup after every tool maintenance, etc. Therefore the domes come from different Lot nos. may have a

No. of effective operating cycle under certain testing criteria.

Most of the dome are designed to use on a hard flat surface; only a few special design according to customers quirement, the contact point can be beneath the rest surface, except for these special design, all damage caused by over-travel.

The condition that the dome cannot snap back to tis original shape.

All metal dome has its designed trip force, excess pressing force may damage the dome and even cause dome collapse.

简体中文

简体中文  繁體中文

繁體中文  English

English